INDIRECT EVAPORATIVE COOLER

Our Indirect section is specifically designed and manufactured to increase efficiencies in cooling and air transfer. Our specially designed evaporative core is manufactured on site and is proprietary to only us. The indirect core is highly efficient, providing 60-65% efficiency when 330 to 360 FPM Face Velocity of air is drawn through the indirect core.

Our horizontal heat exchanger is extruded from non-corrosive, non-metallic rigid polymer. The surface of the tubes are serrated longitudinally to spread the water droplets indefinatlly until they become a monomolecular layer. The heat exchangers tubes comply with the V-O rating by the UL's subject 94 procedues, which indicate that the tubes hold resistance to high temperature flames and exposed heat combustion and shall not be the ignition souce of a fire. The tubes are solvent welded to a 3/16" thick rigid vinyl manifolds at both ends.

The Indirect Evaporative section also incorporates a scavenger fan to exhaust air through the pipes, a water distribution system which includes a water pump and spray nozzles to provide a uniform distribution over the entire heat exchanger, and a filter section to clean and maintain incoming air into the system. The Indirect section's water reservoir is constructed with 18 gauge 304 stainless steel and is double welded to assure that it is 100% leak free. All other parts which are in contact with water are also manufactured from 304 stainless steel to insure long life span and durability

TWO STAGE INDIRECT / DIRECT EVAPORATIVE COOLER:

By incorporating in our Direct Evaporative cooler with our Indirect Evaporative cooler you get the best of both worlds. You get 2 stages of evaporative cooling while offsetting substantial energy costs. These HVAC's come factory assembled, pre-wired, and are self contained, packaged units. The components and materials utilized in the construction of these models meet the requirements of the United States Government Military standards (MIL-OC-22949C), they also conform to the requirements and standards of recognized technical and industrial organizations through out the industry and bear ETL labels. All parts which are incorporated with water or are water bearing are fabricated from 304 stainless steel to assure long life span and durability. A wide range of options are available for Westaire’s two stage coolers: including heating options, and additional cooling coils.

Capacity for standard units range from 3,000 to 25,000 CFM. Larger size units are also available upon further consultation with the factory.

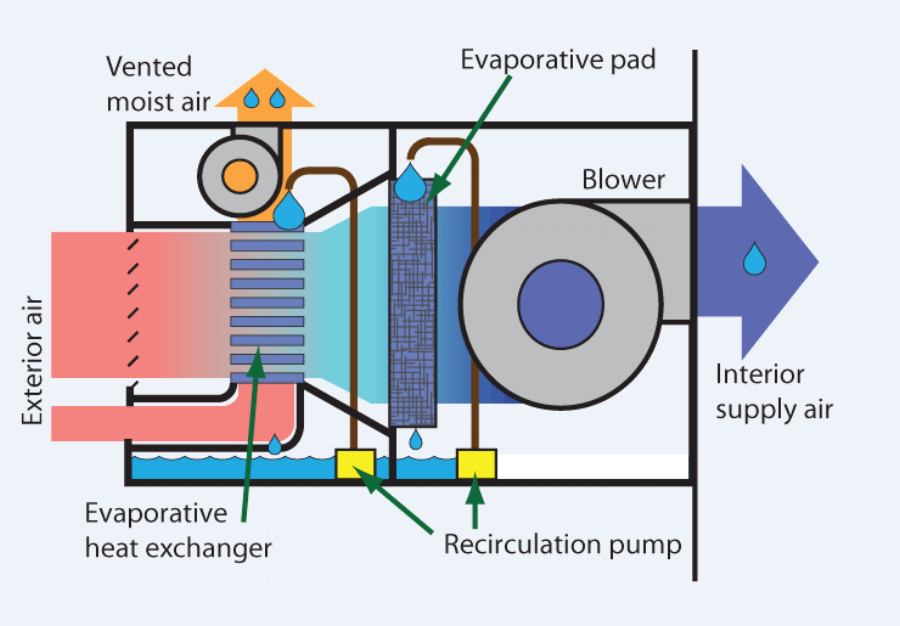

How it works:

First air is drawn through Westaire's custom heat exchanger to provide the first stage of cooling of the outside air. Then the air continues through our Direct Evaporative cooler where the air is mixed with water to add a bit of moister to the air. This is stage 2 of the cooling process. Then the air is pushed into the building by the fan or blower.

These stages of cooling can also be pre-wired to work individually from each other in the case the customer would only like a single stage of cooling either from the indirect or direct.